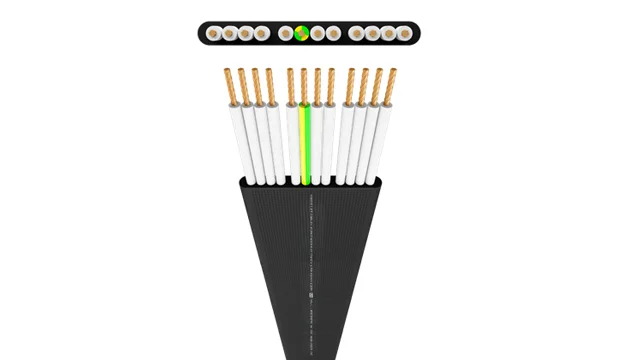

Flat Travelling Cables, made up of electrolytic copper conductor, which provide an electric connection between an Elevator / dumbwaiter car, and a fixed electrical outlet in the hoist way

1. Elevator Suspension Cable for Internal and Panoramic Elevators. 2. Also use as trailing cable for crane, conveyor plant, hoisting and lifting gear, suitable for installation in dry, moist and wet rooms.

IEC 60227-6, EN 50214

CONDUCTOR - Flexible bright annealed bare copper conductor Class 5, manufactured using 99.97%

pure electrolytic grade copper, with more than 100% conductivity, as per IEC 60228

INSULATION - Specially formulated PVC for continuous flexing operation, meeting the requirement

of Type D as per IEC 60227-2

CORE INDENTIFICATION - Grey insulated cores printed with numerals in black & one Y/G for

Ground

OUTER SHEATH - Specially formulated PVC with a blend of Elastomer, for continuous flexing

operation, meeting the requirement of Type ST 3 as per IEC 60227-2, in black color

| Applications | Standard | Conductor | Rated voltage | Minimum temperature | Max. service temperature | Travel speed | Recommended suspension length | Colour | Insulation and sheathing | Loop Suspension elements | Test voltage |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Flexible Cable suspended for maneuver control crane installations. | UNE-EN 60332-1-2, IEC 60332-1-2 | Flexible Cu class 5 | 450 - 750V | -25ºC | 70ºC | 1.6 m/seg | Free 45 m, Fixed 80 m | Black | PVC compound Insulation and Outer Sheath | None | 2500 V |

| NO. OF CORES | CONDUCTOR SIZE | APPROX OVERALL DIMENSIONS h * w | MAX. CR at 20C Ω/Km | Current Carrying Capacity Amps | Min. Loop Diameter mm | |

|---|---|---|---|---|---|---|

| Area mm2 | Nos.-Size | |||||

| 4 | 0.5 | 16/0.20 | 4.20*12.10 | 39.00 | 4 | 300 |

| 12 | 0.5 | 16/0.20 | 4.20 * 31.30 | 39.00 | 4 | 300 |

| 16 | 0.5 | 16/0.20 | 4.20*40.10 | 39.00 | 4 | 300 |

| 24 | 0.5 | 16/0.20 | 9.30*34.70 | 39.00 | 4 | 300 |

| 30 | 0.5 | 16/0.20 | 9.30*43.20 | 39.00 | 4 | 300 |

| NO. OF CORES | AREA mm2 | CONSTRUCTION Nos. - Size | APPROX OVERALL DIMENSIONS h * w | MAX. CR at 20C Ω/Km | Current Carrying Capacity Amps | Min. Loop Diameter Mm |

|---|---|---|---|---|---|---|

| 4 | 0.75 | 24/0.20 | 4.20 * 12.20 | 26.00 | 7 | 300 |

| 12 | 0.75 | 24/0.20 | 4.20 * 32.00 | 26.00 | 7 | 300 |

| 16 | 0.75 | 24/0.20 | 4.20 * 42.00 | 26.00 | 7 | 300 |

| 24 | 0.75 | 24/0.20 | 9.30 * 34.70 | 26.00 | 7 | 300 |

| 30 | 0.75 | 24/0.20 | 9.30 * 43.20 | 26.00 | 7 | 300 |

| NO. OF CORES | CONDUCTOR | APPROX OVERALL DIMENSIONS h * w | MAX. CR at 20C Ω/Km | Current Carrying Capacity Amps | |

|---|---|---|---|---|---|

| AREA mm2 | CONSTRUCTION Nos. - Size | H*W | Ω/Km | Amps | |

| 4 | 1.50 | 48/0.20 | 4.95 * 15.50 | 13.30 | 6 |

| 8 | 1.50 | 48/0.20 | 4.95 * 26.0 | 13.30 | 6 |

| 12 | 1.50 | 48/0.20 | 4.95 * 36.50 | 13.30 | 6 |

| 16 | 1.50 | 48/0.20 | 4.95 * 39.80 | 13.30 | 6 |

| 18 | 1.50 | 48/0.20 | 4.95 * 54.20 | 13.30 | 6 |

| 24 | 1.50 | 48/0.20 | 4.95 * 72.60 | 13.30 | 6 |

| CONDUCTOR | NO. OF CORES | AREA mm2 | CONSTRUCTION Nos. - Size | APPROX OVERALL DIMENSIONS h * w | MAX. CR at 20C Ω/Km | Current Carrying Capacity Amps | Min. Loop Diameter Mm |

|---|---|---|---|---|---|---|---|

| 4 | 2.50 | 80/0.20 | 5.70* 15.50 | 7.98 | 22 | 16 | |

| 12 | 2.50 | 80/0.20 | 5.70* 27.00 | 7.98 | 22 | 16 | |

| 16 | 2.50 | 80/0.20 | 5.70* 39.85 | 7.98 | 22 | 16 |

| CONDUCTOR | NO. OF CORES | AREA mm2 | CONSTRUCTION Nos. - Size | APPROX OVERALL DIMENSIONS h * w | MAX. CR at 20C Ω/Km | Current Carrying Capacity Amps | Min. Loop Diameter Mm |

|---|---|---|---|---|---|---|---|

| 3 | 4 | 56/0.30 | 7.45* 16.70 | 29 | 29 | 29 | |

| 4 | 6 | 84/0.30 | 8.40 * 20.00 | 4.95 | 29 | 37 | |

| 3 | 6 | 84/0.30 | 8.40 * 23.45 | 3.30 | 37 | 37 | |

| 4 | 10 | 140/0.30 | 10.10 * 29.15 | 1.91 | 51 | 51 | |

| 3 | 16 | 126/0.40 | 10.80 * 27.15 | 1.21 | 68 | 68 | |

| 4 | 25 | 196/0.40 | 12.50 * 30.25 | 0.780 | 86 | 86 |

The above data is indicative only and may be revised without prior intimation.

Mardia Cables will not be liable for any damages arising out of incorrect

application of its products.

We can also Manufacture Elevator Control Cable as per customers' requirement.

Fill This Form

To download The Technical Data Sheets