‘MARDIA CABLES’ 3 Core Flat Submersible Cables are used to connect underwater submersible pump-sets with the supply lines, used in Agriculture, Irrigation, Domestic installation & Outdoor applications. These cables are manufactured keeping in mind the critical space requirement, protection towards indefinite immersion in water under specied conditions, protection against rain-water & against ingress of small solid foreign bodies.

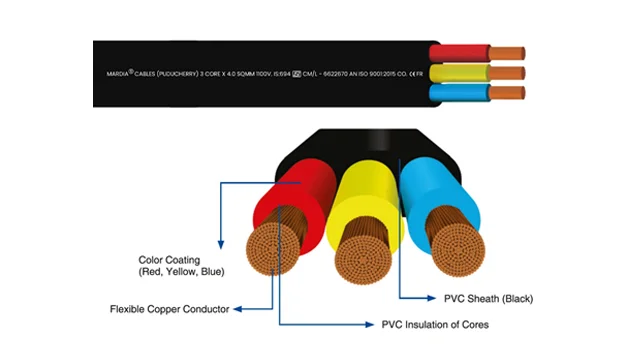

These Cables are produced from best quality electrolytic copper, which is drawn, annealed on-line & bunched on automatic machines, to ensure flexibility and uniform resistance. Co-extruded Insulation with special grade PVC, for better electrical properties. Cores are laid parallel & Outer Sheathed with highly abrasion resistant PVC compound which is impervious to grease, oil and water etc

Online wire drawing with annealing

Co-extruded PVC Insulation, for better Insulation & Electrical properties

Online High Voltage Spark Testing, ensuring no weak spots

Automatic on-line critical diameter control

Stringent Quality Control

| NO. OF CORES | CONDUCTOR | INSULATION THICKNESS | SHEATH THICKNESS | MAX. CR at 20°C Ω/Km | Current Carrying Capacity - Amps | |||

|---|---|---|---|---|---|---|---|---|

| AREA mm2 | CONSTRUCTION Nos. - Size | THICKNESS mm | DIA mm | THICKNESS mm | DIAMETER- h*w mm | 13.30 | 16 | |

| 3 | 1.50 | 22/0.30 | 0.60 | 2.70 | 0.90 | 4.60 * 10.00 | 13.30 | 16 |

| 3 | 2.50 | 36/0.30 | 0.70 | 3.40 | 1.00 | 5.50 * 12.50 | 7.98 | 22 |

| 3 | 4 | 56/0.30 | 0.80 | 4.00 | 1.00 | 7.45 * 16.40 | 4.95 | 29 |

| 3 | 6 | 84/0.30 | 0.80 | 4.55 | 1.10 | 8.40 * 18.60 | 3.30 | 37 |

| 3 | 10 | 80/0.40 | 1.00 | 5.90 | 1.40 | 10.10 * 22.50 | 1.91 | 51 |

| 3 | 16 | 126/0.40 | 1.00 | 7.20 | 1.40 | 10.80 * 27.00 | 1.21 | 68 |

| 3 | 25 | 196/0.40 | 1.20 | 8.70 | 2.00 | 12.70 * 30.00 | 0.780 | 86 |

| 3 | 35 | 276/0.40 | 1.20 | 9.90 | 2.00 | 14.00 * 33.50 | 0.554 | 110 |

| NO. OF CORES | CONDUCTOR | INSULATION | SHEATH | MAX. CR at 20°C Ω/Km | Current Carrying Capacity - Amps | |||

|---|---|---|---|---|---|---|---|---|

| AREA mm2 | CONSTRUCTION Nos. - Size | THICKNESS mm | DIA mm | THICKNESS mm | DIAMETER- h*w mm | |||

| 4 | 1.50 | 22/0.30 | 0.60 | 2.70 | 1.00 | 4.60 * 13.20 | 13.30 | 16 |

| 4 | 2.50 | 36/0.30 | 0.70 | 3.40 | 1.10 | 5.50 * 16.50 | 7.98 | 22 |

| 4 | 4 | 56/0.30 | 0.80 | 4.00 | 1.20 | 7.20 * 20.00 | 4.95 | 29 |

| 4 | 6 | 84/0.30 | 0.80 | 4.55 | 1.20 | 6.90 * 21.30 | 3.30 | 37 |

| 4 | 10 | 80/0.40 | 1.00 | 5.90 | 1.50 | 8.90 * 27.20 | 1.91 | 51 |

| 4 | 16 | 126/0.40 | 1.00 | 7.20 | 1.50 | 12.00 * 36.20 | 1.21 | 68 |

The above data is indicative only and may be revised without prior intimation. Mardia cables will not be liable damages arising out of incorrect application of its products.

| HP | Amps |

|---|---|

| 5 | 7.5 |

| 7.5 | 11 |

| 10 | 14.9 |

| 12.5 | 18.9 |

| 15.5 | 22.5 |

| 17.5 | 25.2 |

| 20 | 28.4 |

| 25 | 35.6 |

| 30 | 42.3 |

| 35 | 50.4 |

| 40 | 58.1 |

| 45 | 62.1 |

| 50 | 67.5 |

| 55 | 73.8 |

| 60 | 81 |

| 65 | 87.3 |

| 70 | 93.6 |

| 75 | 101 |

| 80 | 108 |

- Coiled Submersible cable should always be spread out before using, to avoid overheating in use

- Ensure proper joining of the cable in order to avoid failure & short circuit

- Proper care should be taken while inserting the cable in the bore well, to avoid slicing of the Outer Sheath

Fill This Form

To download The Technical Data Sheets